درباره ما

اسپری های صنعتی از جمله ابزارهای حیاتی در صنایع مختلف هستند.

شرکت رسیس با چندین دهه تجربه در زمینه تحقیق، توسعه و تولید اسپری های صنعتی به عنوان نامی شناخته شده و قابل اعتماد در این صنعت مطرح شده است. در طول سال ها، این شرکت تخصص خود را توسعه داده و به یک مجموعه قابل اعتماد در بازار تبدیل شده است. این تجربه گسترده نشان دهنده تعهد رسیس به ارائه راه حل های درجه یک در زمینه اسپری های صنعتی است. یکی از عوامل کلیدی موفقیت رسیس، اتکای آن به تیمی بسیار ماهر و متخصص به همراه تجهیزات پیشرفته است. این شرکت اهمیت داشتن نیروی کار اختصاصی و فناوری پیشرفته برای ماندن در خط مقدم نوآوری را درک می کند. این ترکیب استراتژیک رسیس را قادر می سازد تا با تولید اسپری های صنعتی با کیفیت بالا، به طور مداوم انتظارات مشتری را برآورده کند و از آن فراتر رود.

محصولات رسیس

برای اطلاعات بیشتر در مورد هر محصول، روی لینک مربوطه کلیک کنید

Rasis Products

For More Detailed Information On Each Product

اسپری WD40

WD-40 یکی از محصولات روان کننده، ضد زنگ و محافظ است و در صنایع و مصارف مختلف مورد استفاده قرار می گیرد.

Rasis

اسپری ضد تراشه جوش

اسپری های ضد تراشه در روش های مختلف جوشکاری از چسبندگی پاشش ناشی از جوشکاری به ابزار، تجهیزات و سطوح جوشی جلوگیری می کنند.

Rasis

اسپری سیلیکون

اسپری سیلیکون روی سطح قالب اسپری می شود تا مواد به قالب نچسبد و عمر قالب را افزایش دهد.

Rasis

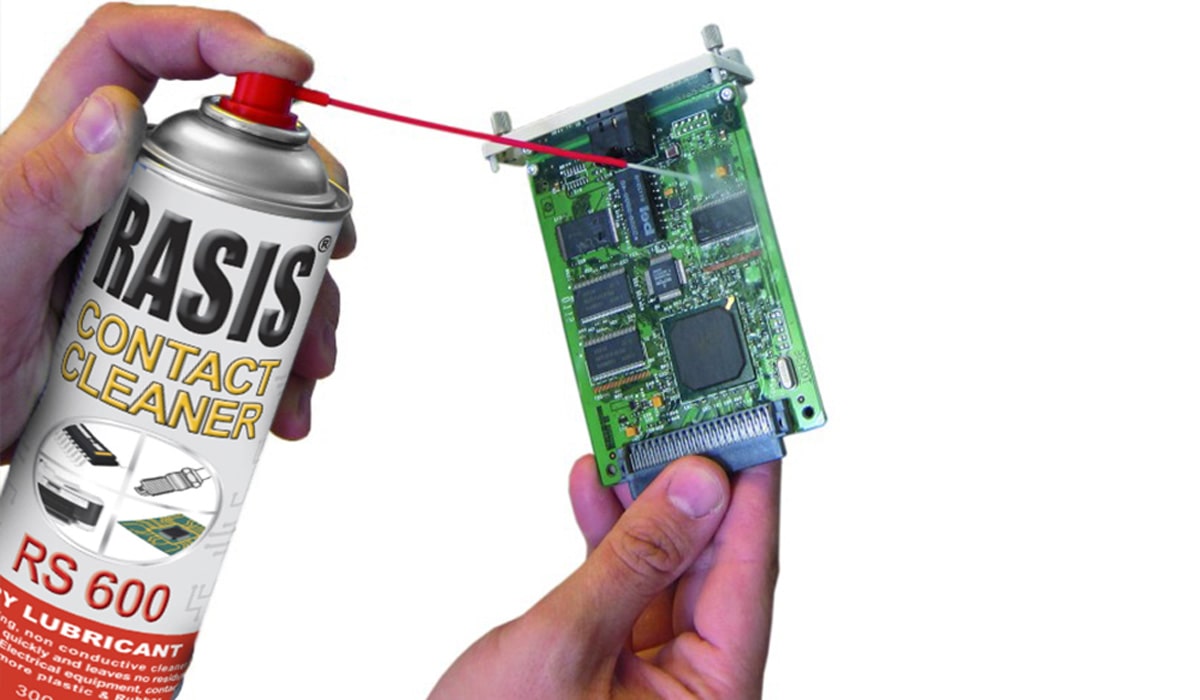

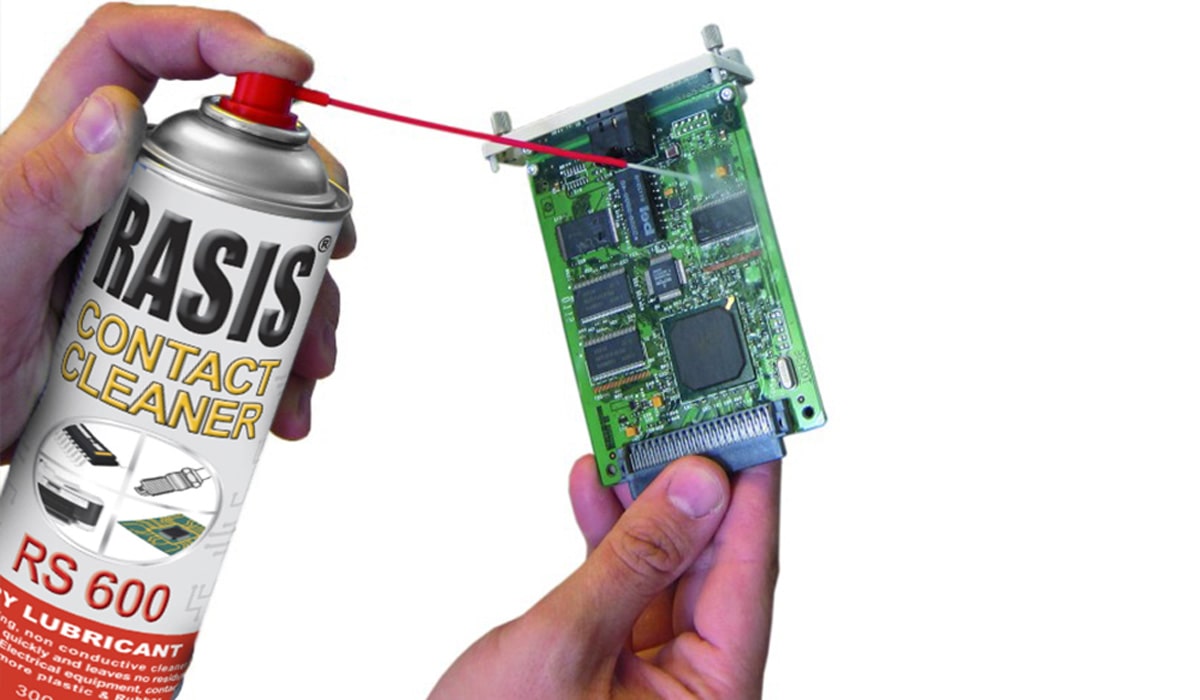

اسپری کنتاکت شوی

اسپری های کنتاکت شوی به دلیل خاصیت ضد اکسیداسیون و انعطاف پذیری معمولاً برای استفاده در محیط های الکترونیکی مناسب هستند.

Rasis

چسب فوری

سیانواکریلات یک ماده شیمیایی است که به طور گسترده برای ساخت چسب های قوی استفاده می شود، چسب قطره ای 123 در مدت زمان بسیار کوتاهی روی سطح خشک می شود.

Rasis

نوار چسب برق

نوار چسب برق نوع خاصی از نوار چسب است که برای ایجاد اتصالات الکتریکی در ساخت اتصالات برقی و تعمیرات استفاده می شود.

Rasis

نوار چسب کاغذی

چسب های کاغذی به دلیل استفاده از کاغذ در ساختار آن سبک و ناپایدار هستند، بیشتر برای مصارف موقت استفاده می شوند.

Rasis

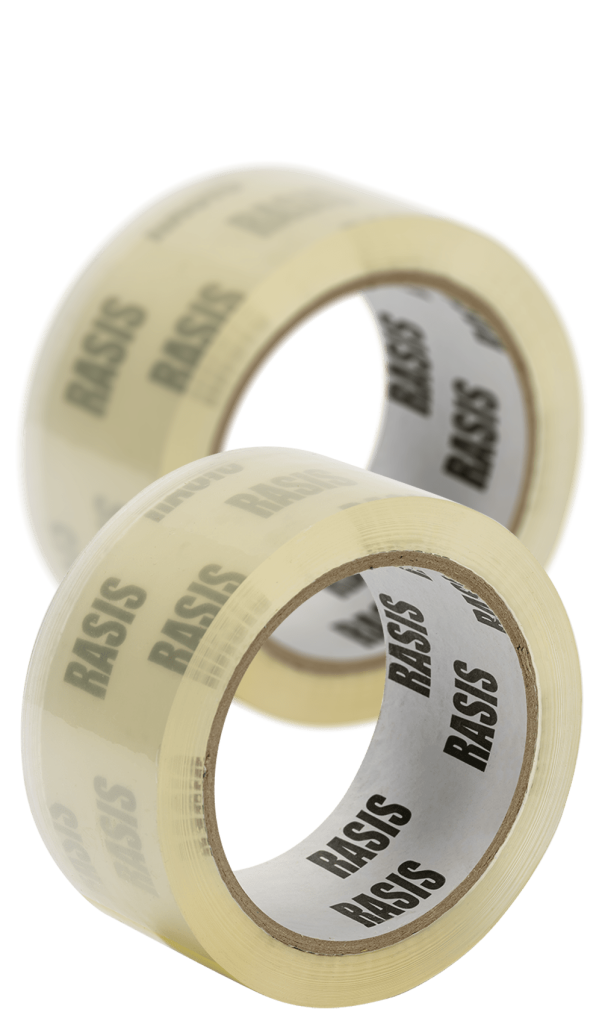

نوار چسب کریستال

نوار چسب کریستال ترکیبی از یک ماده و یک لایه چسب است و برای چسباندن یا اتصال اجسام به یکدیگر استفاده می شود.

Rasis

نوار چسب نسوز

چسب های نسوز الکتریکی یا چسب های حرارتی در برابر حرارت زیاد مقاوم هستند و برای اتصالات الکتریکی استفاده می شوند.

Rasis

WD40

اسپری روان کننده WD40 چیست؟

Rasis Activities

The Company’s Activities Include Three Following Branches

فعالیتهای رسیس

فعالیتهای شرکت شامل سه شاخه زیر می باشد

فرمولاسیون اسپری ها

فرمولاسیون و تولید اسپری و سایر محصولات شیمیایی:

ما در این زمینه با استفاده از تجهیزات دقیق و دقیق و کادر مجرب خود انواع اسپری های مورد استفاده در آزمایشگاه های کنترل کیفی و تحقیقاتی را تولید و به کارخانه های دیگر عرضه می کنیم. ظرفیت تولید ما در این زمینه پانصد هزار اسپری در سال است.

تولید اسپری

تولید اسپری و مواد شیمیایی:

در این زمینه انواع اسپری ها از جمله روان کننده ها، خاک رس ها، جداکننده ها، رنگ ها، واکس ها، پاک کننده ها، آشکارسازهای ترک، اسپری های جوشکاری و انواع خاک رس، مواد شوینده و رنگ تولید می شود. ظرفیت تولید شرکت ما در این زمینه دو میلیون اسپری و خاک رس صد تنی، رنگ و مواد شوینده و پاک کننده در سال می باشد.

Customers

"Discover Our Exclusive Services For Valued Customers"

مشتریان ما

"خدمات انحصاری ما را برای مشتریان ارزشمند کشف کنید"

ما مفتخریم که طیف گسترده ای از خدمات انحصاری را ارائه می دهیم که برای رفع نیازها و ترجیحات منحصر به فرد مشتریان عزیز طراحی شده اند. تعهد ما به کیفیت تزلزل ناپذیر است. ما تلاش می کنیم در هر مرحله از انتظارات شما فراتر برویم. رضایت شما اولویت ما است. از خدمات شخصی سازی شده متناسب با نیازهای خاص خود بهره مند شوید. بازخورد شما مهم است. ما به طور مداوم بر اساس بازخورد شما در حال بهبود هستیم تا تجربه کلی شما را افزایش دهیم. امروز به خانواده راسیس بپیوندید و اجازه دهید سفر شما را با خدمات بی نظیر خود ارتقا دهیم. رضایت شما نه تنها هدف ماست بلکه وعده ماست.

Why Rasis

Why Are We The Best Option Among Competitors?

چرا رسیس ؟

چرا ما بهترین گزینه در بین رقبا هستیم؟

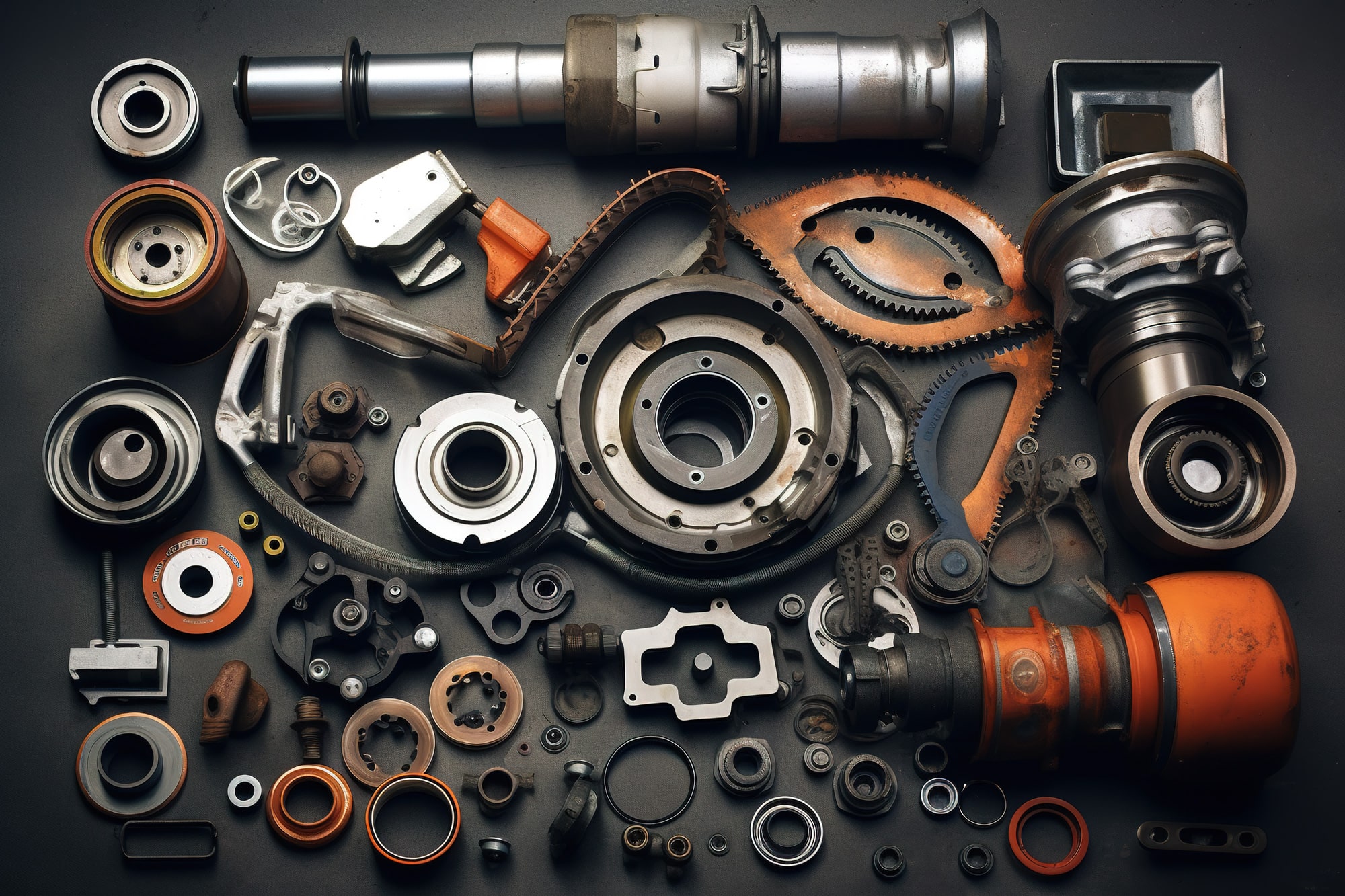

Some applications

In The Following Section, Some Of The Applications Of Our

Products In Different Industries Are Mentioned

برخی از کاربردها

در قسمت زیر به برخی از کاربردهای محصولات ما در صنایع مختلف اشاره شده است

پاک کننده تراشه جوش Co2

تمیز کردن بردهای الکترونیکی

حذف رسوبات چربی و روغن

اتصالات الکتریکی کثیف یا اکسید شده

اتصالات الکتریکی ناپایدار یا نامناسب

تعمیر و نگهداری دستگاه های الکترونیکی

ما در تولید طیف متنوعی از اسپریها، شامل دستههای مختلف مانند روانکنندهها، جداکنندهها، رنگها، مومها، عوامل تمیزکننده، آشکارسازهای ترک، اسپریهای جوش و انواع خاصی از مواد شوینده و رنگها تخصص داریم. این سبد محصولات گسترده نشان دهنده تعهد ما به پاسخگویی به طیف گسترده ای از نیازها و کاربردهای صنعتی است. با ارائه مجموعه ای جامع از اسپری ها، هدف ما ارائه راه حل های همه کاره است که نیازهای خاص مشتریان متنوع ما را برآورده می کند.

شرکت ما دارای ظرفیت تولید قوی در این زمینه با توانایی تولید سالانه دو میلیون اسپری و صد تن رنگ و مواد شوینده و پاک کننده می باشد. این ظرفیت تولید قابل توجه نشان دهنده تعهد ما به پاسخگویی به تقاضاهای بازار و اطمینان از عرضه مطمئن و ثابت محصولات با کیفیت است. با استفاده از فرآیندهای تولید کارآمد و فناوری پیشرفته، ما در تلاش هستیم تا موقعیت خود را به عنوان یک ارائه دهنده پیشرو در اسپری های صنعتی حفظ کنیم و در عین حال استانداردها و انتظارات دقیق مشتریان خود را برآورده کنیم.

کاتالوگ

می توانید آخرین اطلاعات فنی و کاتالوگ های شرکت را دانلود کنید.

درباره ما

اسپری های صنعتی از جمله ابزارهای حیاتی در صنایع مختلف هستند.

شرکت رسیس با چندین دهه تجربه در زمینه تحقیق، توسعه و تولید اسپری های صنعتی به عنوان نامی شناخته شده و قابل اعتماد در این صنعت مطرح شده است. در طول سال ها، این شرکت تخصص خود را توسعه داده و به یک مجموعه قابل اعتماد در بازار تبدیل شده است. این تجربه گسترده نشان دهنده تعهد رسیس به ارائه راه حل های درجه یک در زمینه اسپری های صنعتی است. یکی از عوامل کلیدی موفقیت رسیس، اتکای آن به تیمی بسیار ماهر و متخصص به همراه تجهیزات پیشرفته است. این شرکت اهمیت داشتن نیروی کار اختصاصی و فناوری پیشرفته برای ماندن در خط مقدم نوآوری را درک می کند. این ترکیب استراتژیک رسیس را قادر می سازد تا با تولید اسپری های صنعتی با کیفیت بالا، به طور مداوم انتظارات مشتری را برآورده کند و از آن فراتر رود.

محصولات رسیس

برای اطلاعات بیشتر در مورد هر محصول، روی لینک مربوطه کلیک کنید

اسپری ضد تراشه جوش

اسپری های ضد تراشه در روش های مختلف جوشکاری از چسبندگی پاشش ناشی از جوشکاری به ابزار، تجهیزات و سطوح جوشی جلوگیری می کنند.

Rasis

اسپری کنتاکت شوی

اسپری های کنتاکت شوی به دلیل خاصیت ضد اکسیداسیون و انعطاف پذیری معمولاً برای استفاده در محیط های الکترونیکی مناسب هستند.

Rasis

نوار چسب کریستال

نوار چسب کریستال ترکیبی از یک ماده و یک لایه چسب است و برای چسباندن یا اتصال اجسام به یکدیگر استفاده می شود.

Rasis

نوار چسب برق

نوار چسب برق نوع خاصی از نوار چسب است که برای ایجاد اتصالات الکتریکی در ساخت اتصالات برقی و تعمیرات استفاده می شود.

Rasis

نوار چسب نسوز

چسب های نسوز الکتریکی یا چسب های حرارتی در برابر حرارت زیاد مقاوم هستند و برای اتصالات الکتریکی استفاده می شوند.

Rasis

چسب فوری

سیانواکریلات یک ماده شیمیایی است که به طور گسترده برای ساخت چسب های قوی استفاده می شود، چسب قطره ای 123 در مدت زمان بسیار کوتاهی روی سطح خشک می شود.

Rasis

نوار چسب کاغذی

چسب های کاغذی به دلیل استفاده از کاغذ در ساختار آن سبک و ناپایدار هستند، بیشتر برای مصارف موقت استفاده می شوند.

Rasis

اسپری سیلیکون

اسپری سیلیکون روی سطح قالب اسپری می شود تا مواد به قالب نچسبد و عمر قالب را افزایش دهد.

Rasis

اسپری WD40

WD-40 یکی از محصولات روان کننده، ضد زنگ و محافظ است و در صنایع و مصارف مختلف مورد استفاده قرار می گیرد.

Rasis

WD40

اسپری روان کننده WD40 چیست؟

فعالیتهای رسیس

فعالیتهای شرکت شامل سه شاخه زیر می باشد

فرمولاسیون اسپری ها

فرمولاسیون و تولید اسپری و سایر محصولات شیمیایی:

ما در این زمینه با استفاده از تجهیزات دقیق و دقیق و کادر مجرب خود انواع اسپری های مورد استفاده در آزمایشگاه های کنترل کیفی و تحقیقاتی را تولید و به کارخانه های دیگر عرضه می کنیم. ظرفیت تولید ما در این زمینه پانصد هزار اسپری در سال است.

تولید اسپری

تولید اسپری و مواد شیمیایی:

در این زمینه انواع اسپری ها از جمله روان کننده ها، خاک رس ها، جداکننده ها، رنگ ها، واکس ها، پاک کننده ها، آشکارسازهای ترک، اسپری های جوشکاری و انواع خاک رس، مواد شوینده و رنگ تولید می شود. ظرفیت تولید شرکت ما در این زمینه دو میلیون اسپری و خاک رس صد تنی، رنگ و مواد شوینده و پاک کننده در سال می باشد.

مشتریان ما

"خدمات انحصاری ما را برای مشتریان ارزشمند کشف کنید"

ما مفتخریم که طیف گسترده ای از خدمات انحصاری را ارائه می دهیم که برای رفع نیازها و ترجیحات منحصر به فرد مشتریان عزیز طراحی شده اند. تعهد ما به کیفیت تزلزل ناپذیر است. ما تلاش می کنیم در هر مرحله از انتظارات شما فراتر برویم. رضایت شما اولویت ما است. از خدمات شخصی سازی شده متناسب با نیازهای خاص خود بهره مند شوید. بازخورد شما مهم است. ما به طور مداوم بر اساس بازخورد شما در حال بهبود هستیم تا تجربه کلی شما را افزایش دهیم. امروز به خانواده راسیس بپیوندید و اجازه دهید سفر شما را با خدمات بی نظیر خود ارتقا دهیم. رضایت شما نه تنها هدف ماست بلکه وعده ماست.

چرا رسیس ؟

چرا ما بهترین گزینه در بین رقبا هستیم؟

برخی از کاربردها

در قسمت زیر به برخی از کاربردهای محصولات ما در صنایع مختلف اشاره شده است

پاک کننده تراشه جوش Co2

تمیز کردن بردهای الکترونیکی

حذف رسوبات چربی و روغن

اتصالات الکتریکی کثیف یا اکسید شده

اتصالات الکتریکی ناپایدار یا نامناسب

تعمیر و نگهداری دستگاه های الکترونیکی

ما در تولید طیف متنوعی از اسپریها، شامل دستههای مختلف مانند روانکنندهها، جداکنندهها، رنگها، مومها، عوامل تمیزکننده، آشکارسازهای ترک، اسپریهای جوش و انواع خاصی از مواد شوینده و رنگها تخصص داریم. این سبد محصولات گسترده نشان دهنده تعهد ما به پاسخگویی به طیف گسترده ای از نیازها و کاربردهای صنعتی است. با ارائه مجموعه ای جامع از اسپری ها، هدف ما ارائه راه حل های همه کاره است که نیازهای خاص مشتریان متنوع ما را برآورده می کند.

شرکت ما دارای ظرفیت تولید قوی در این زمینه با توانایی تولید سالانه دو میلیون اسپری و صد تن رنگ و مواد شوینده و پاک کننده می باشد. این ظرفیت تولید قابل توجه نشان دهنده تعهد ما به پاسخگویی به تقاضاهای بازار و اطمینان از عرضه مطمئن و ثابت محصولات با کیفیت است. با استفاده از فرآیندهای تولید کارآمد و فناوری پیشرفته، ما در تلاش هستیم تا موقعیت خود را به عنوان یک ارائه دهنده پیشرو در اسپری های صنعتی حفظ کنیم و در عین حال استانداردها و انتظارات دقیق مشتریان خود را برآورده کنیم.

کاتالوگ

می توانید آخرین اطلاعات فنی و کاتالوگ های شرکت را دانلود کنید.